Takt Cornerstones

Takt Requirements

In order for Takt to achieve its promises, it has to be created and managed in specific ways. The section below provides the minimum requirements for a scheduling system to be considered Takt Planning and Takt Control:

Your Takt Plan must…

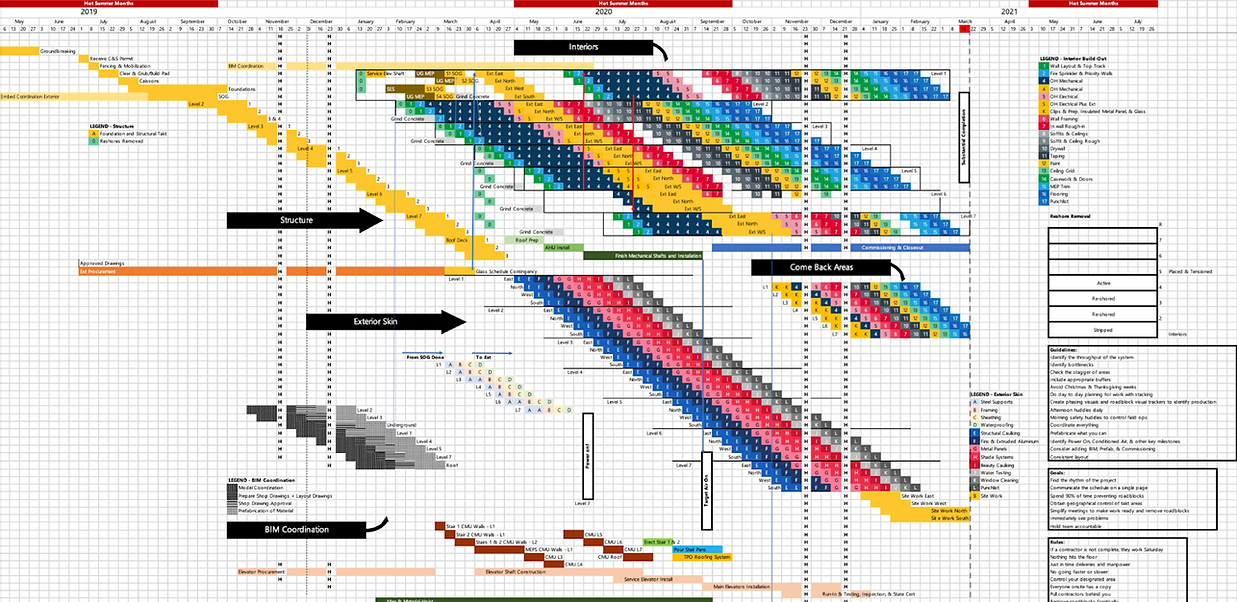

- Be a visual schedule showing time and space

- Show work, trade (value) and logistical flow

- Visualize the work per trade in different colors - colors stands for trades

- Be scheduled on a rhythm for the whole phase

- Be planned with the appropriate buffers

- Stabilize the pace of work with one-process flow and limiting work in process

- Have a reasonable overall project duration

If your plan does not meet these requirements, it is not a Takt plan.

For takt to work really well...

A “Takt” is a multi-dimensional unit for a construction project and enables us to visualize time and space. This format also enables the use of mathematical, scientific, and scalable operations that enable us to plan and execute work in hours and days, not only weeks.

Takt is the basis for production in manufacturing and should also be used for production in construction. Companies in the automotive industry like Toyota or Volkswagen and others are all based on Takt or rate of flow, then pull. “Flow where you can, pull when you can’t”. Takt streamlines the value creation processes and enables all pull systems to efficiently support the Takt-ed production rhythm. Because of this, it creates stability, leveled work and ultimately protects workers.

This ensures we limit excess manpower levels and excess material inventory levels, which makes you more money! Takt-ed projects have smoother finishes, less needed manpower, less material inventory, and make more money because rhythm creates a backbone where the team can win in a balanced and fun way.

Schedule health

To be a healthy Takt plan your schedule must comply with the Takt Schedule Health Metrics…

- The Value Parametric - The value parametric divides the Takts that are used in a Takt plan by the empty Takts. This parametric tracks the value being provided in the flow of the work which should range between .5 and 2.5 when calculated as an ideal. This ensures the Takt plan is structured in a way to provide maximum value.

- The Efficiency Parametric - The efficiency parametric compares the number of Takt wagons and Takt sequences and ensures the phase does not have over a 1:3 ratio in the number of each in comparison to each other. The ideal metric should be .3 to 3.0 when calculating the metric. This ensures the Takt sequences are structured ideally for optimum efficiency.

- The Stability Parametric - The stability parametric divides the train buffers by the end buffers. The ideal metric for this is .5 to 2.0 ideally and this metric ensures you have a Takt plan that is stable with the appropriate ratio of buffers.

To be reliable it must also…

- Have trade buy-in.

- Includes buffers according to the risk analysis.

- Have the proper percentages of flow:

- >80% for trade flow

- >60% for workflow

- Have all ancillary, infrastructure, and support activities included in it.

- Show interdependence ties between phases.

- Show critical milestones and where they land in the schedule.

- Show come-back areas.

- Show the status of the work during the project

- Show the impact of weather on the Takt plan.

- Be reviewed with a wider team before use as a part of a risk and opportunity analysis.

If your plan does not have these, it is not healthy, and should not be considered a complete Takt plan.

This guide will be updated periodically to better guide the industry with Takt planning. We are looking forward for your feedback.