Takt 101

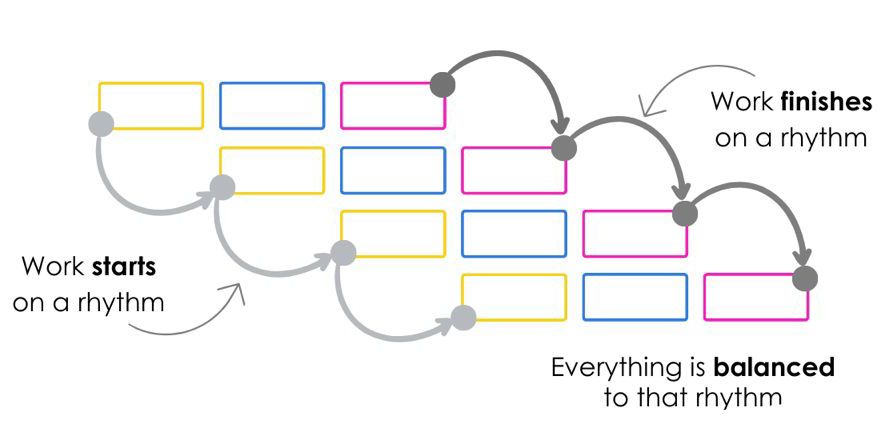

A Schedule formatted this way will provide a plan that has Rhythm, Continuity and Consistency.

• Rhythm

• Consistency

All Construction schedules should be formatted like this:

And look like this:

Prediction: Takt Construction will Dominate

There are many things in this industry that cause waste and variation: siloed command and control leaders, bad contracting systems, unstable markets, bad construction practices, a disrespect for people, and bad systems like cpm (critical path method) in the way it is used today. These have become our targets in a social cause to correct construction’s downward trajectory and create safe and healthy environments for people. They are targets because they create waste and variation, which is our enemy. It is only a matter of time before they are removed and replaced. They have already become unpopular even if some of them are still considered necessary.

There will be a day when leaders will have to be collaborative, open, and vulnerable. There will be a day when design-bid-build contracts become a very small percentage or go away completely. There will be a day when the market stabilizes again. There will be a day when disrespect for people will no longer be tolerated. And there will be day when old, antiquated, and incorrect systems will be removed and replaced. It is coming. The question is: do we want to be on the forefront of that or on the tail end? Do we want to be like blockbuster or netflix?

I developed the takt production system® as the construction equivalent of the toyota production system®. The last planner® system & scrum are components utilized in the system. The takt production system® Will revolutionize the industry. That’s a bold statement, and it’s True. Here are a few things to consider:

Concept 1: lean is based on takt first.

Lean is based on takt and then pull. It is not only based on pull like we have been told. Production assembly lines in manufacturing primarily operate on a takt time that can be interrupted by an andon if there is a defect or problem. Motors, wheels, and other assemblies are then “Pulled into that line” based on a kanban system. With these systems, flow is achieved by keeping the flow units going the same speed and the same distance apart.

Concept 2: construction should be organized as a production system.

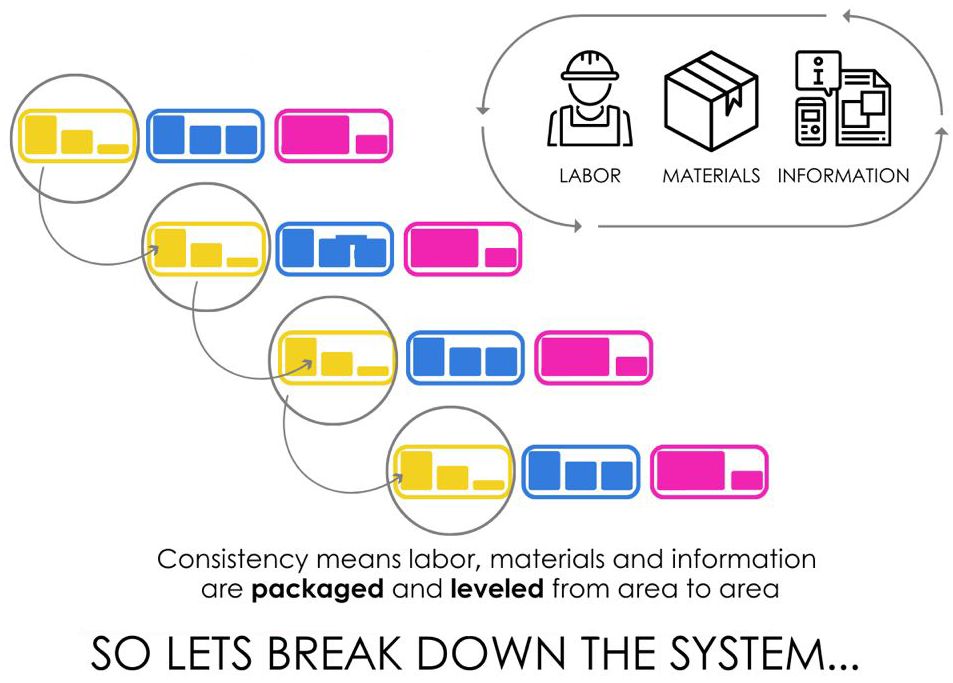

So, how do we get all our trades going at different speeds with differing levels of effort in their work to go the same speed and the same distance apart? Glad you asked: we package them into train cars. Imagine all our trades like individual vehicles that are going different speeds and as different sized units. (I’m imagining the movie mad max here.) how could you get them to flow? Load them onto train cars is the answer. Some cars would be loaded with multiple vehicles, and some cars would only load with a part of a larger vehicle, but it would all be leveled and coupled together just like a car manufacturing assembly line. Then, we would run that train – going the same speed the same distance apart – through the project in a production line from zone to zone.

So, how do we get all our trades going at different speeds with differing levels of effort in their work to go the same speed and the same distance apart? Glad you asked: we package them into train cars. Imagine all our trades like individual vehicles that are going different speeds and as different sized units. (I’m imagining the movie mad max here.) how could you get them to flow? Load them onto train cars is the answer. Some cars would be loaded with multiple vehicles, and some cars would only load with a part of a larger vehicle, but it would all be leveled and coupled together just like a car manufacturing assembly line. Then, we would run that train – going the same speed the same distance apart – through the project in a production line from zone to zone.

Concept 3: trains of trades together in a phase are the “Flow unit” in

Construction.

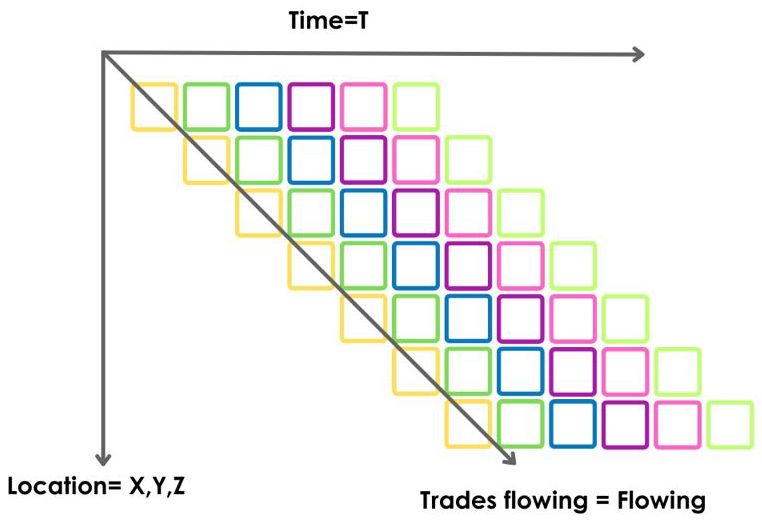

Why is this so important? Because the process, meaning the workers, tools, Equipment, and materials – the trade as a whole working the same speed With other trades is the flow unit in construction. It is the thing that Should be flowing. Just like in a car manufacturing plant, the car is the Flow unit, and in a hospital, the patient is the flow unit. In construction, the Trades or the processes is the flow unit. So, we can never flow without Having trades flowing. We can never have trades flowing without Organizing them into a production line as a train and that means we Should only ever see a master schedule that accommodates this concept. This is where takt becomes our base. Only a schedule with time shown Across the top, zones shown along the side, and takt wagons (or box Cars), which represent the ‘process’ shown in the middle – and all going From area to area at the same speed and the same distance apart – can Become our master schedule.

Why is this so important? Because the process, meaning the workers, tools, Equipment, and materials – the trade as a whole working the same speed With other trades is the flow unit in construction. It is the thing that Should be flowing. Just like in a car manufacturing plant, the car is the Flow unit, and in a hospital, the patient is the flow unit. In construction, the Trades or the processes is the flow unit. So, we can never flow without Having trades flowing. We can never have trades flowing without Organizing them into a production line as a train and that means we Should only ever see a master schedule that accommodates this concept. This is where takt becomes our base. Only a schedule with time shown Across the top, zones shown along the side, and takt wagons (or box Cars), which represent the ‘process’ shown in the middle – and all going From area to area at the same speed and the same distance apart – can Become our master schedule.

Concept 4: we should make critical flow paths, not critical paths. This is the toyota production system translated to construction. What About this “Critical path” we always talk about in construction Scheduling? It should not exist. We need to replace that concept right Here and now with the term critical flow path or path of critical flow. What’s the difference? A critical path is the longest path in the schedule With zero float, where if any activity is delayed,

it delays the entire project. A path of critical flow is like a rail line. On a rail line you have trains Separated by buffers. A path of critical flow is a schedule that connects Each phase or train together. Just like a rail line, there are buffers between Trains and at the end. Without phases organized as trains (in a flow) and Buffers in between, we will never flow in construction. This is basically Critical chain theory.

Concept 5: last planner® & scrum work well outside of cpm.

They work and they work well! They work with the right overall master Schedule as the base. Everything wrong with last planner® & scrum is cpm The way we use it today. If you remove cpm from the systems, they work Perfectly and pair to create a complete system. The takt plan creates the Rhythm and optimization; last planner® creates the collaborative culture And short interval planning technique; and scrum pulls all resources into The system with design, pre-construction, and construction Administration.

They work and they work well! They work with the right overall master Schedule as the base. Everything wrong with last planner® & scrum is cpm The way we use it today. If you remove cpm from the systems, they work Perfectly and pair to create a complete system. The takt plan creates the Rhythm and optimization; last planner® creates the collaborative culture And short interval planning technique; and scrum pulls all resources into The system with design, pre-construction, and construction Administration.

In my opinion, cpm is on its way out as the primary master scheduling technique, and the takt production system® is on its way in. Cpm may endure as a modified system, and cpm software may still be used to create simple waterfall schedules, but they must be governed by takt and takt critical flow paths. Takt planning, steering, and control will dominate the lean construction scheduling world by 2030 or sooner!

Schedules for construction were always supposed to be Formatted in a time by location format. Then it becomes a 4-d Schedule. Once you can see all the dimensions you can see Production principles, lean construction, flow, and all other Components of a successful project. We’re about to take a Closer look at each component.

• TPS® Recap

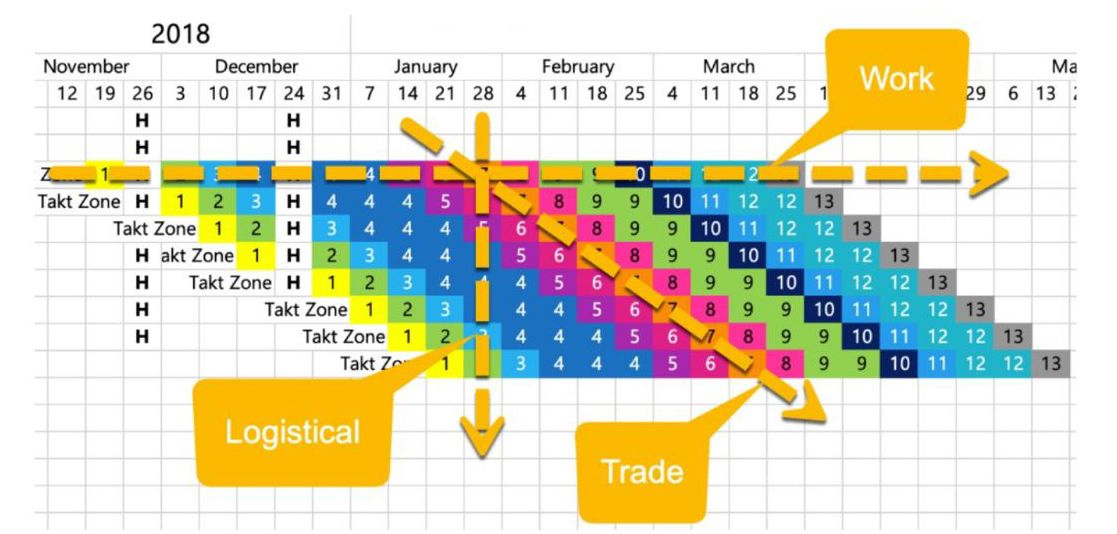

A takt plan is the ideal first planner™ tool that pairs with IPS®. It is a planning method that brings flow to the project. Additionally, it prepares work for Last Planner® and Scrum by queueing work up for those systems with workflow, trade flow, and logistical flow. It’s effective because the plan is crafted early on when information, material procurement, and labor can align with the flow and sequence of the project.

A Takt Plan is:

- A visual location-based schedule showing time and space

- Showing work, trade, and logistical flow (when, what, where, who, how)

- Scheduled on a rhythm

- With the appropriate buffers

- That stabilizes the pace of work with one-process flow and limiting work in process

- With a reasonable overall project duration

It is a system that creates stability in the field which enables:

- Aditional team and builder capacity

- Consistent crew sizes

- consistent material inventory levels

- The ability to find and remove roadblocks ahead of the work

- The ability to finish as we go

- A solid quality program

It is the Only Scheduling System that shows all three types of flow:

- Workflow

- Trade Flow, and ,

- Logistical Flow

Flow is identified by Evaluating the schedule’s:

- Rhythm

- Continuity, and,

- Consistency

The structure not only enables, But almost forces the user to obey Four key production laws:

- Little's Law

- The law of Bottlenecks

- The law of the Effects of variation, and,

- Kingman's Formula

Which Results in:

- Healther project durations

- A Complex project communicated in a simple to read visual schedule

- A respectful and stable environment

- The ability to gain time in the overall project duration